Speaker Cabinet Design Fundamentals: Speaker Cabinet Design Plans

Building a killer speaker cabinet in Jakarta Selatan style means understanding the basics. It’s not just about slapping some wood together; it’s about crafting a resonant chamber that brings your audio to life. Get the design wrong, and your awesome speakers sound like a tin can. Get it right, and your neighbours will be begging for a listen (or maybe calling the police, depending on your taste in music!).

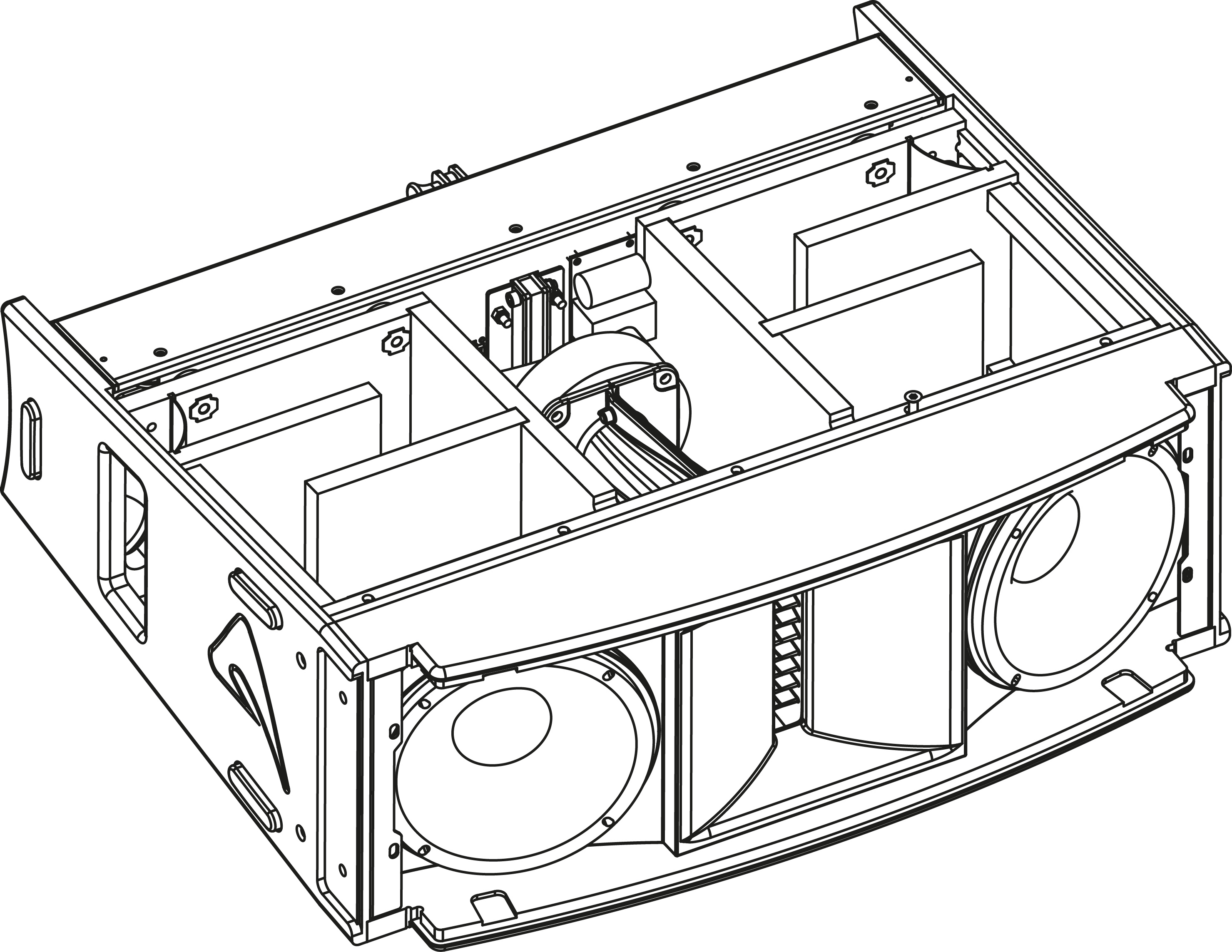

Basic Speaker Cabinet Design

Let’s build a simple, yet effective, sealed rectangular cabinet. We’ll use standard dimensions for a small bookshelf speaker: internal dimensions of 12″ (height) x 8″ (width) x 6″ (depth). This design is perfect for a single 6.5″ woofer. Remember, these are internal dimensions; you’ll need to add material thickness for the external dimensions. We’ll use 3/4″ thick medium-density fiberboard (MDF) for its density and affordability.

Speaker cabinet design plans – Parts List:

- Four pieces of MDF: 12″ x 8″ (front and back panels)

- Two pieces of MDF: 12″ x 6″ (side panels)

- Two pieces of MDF: 8″ x 6″ (top and bottom panels)

- Wood glue

- Screws (1 1/4″ length)

- 6.5″ woofer speaker

- Speaker terminals

- Damping material (polyfill or similar)

Assembly:

- Apply wood glue to the edges of the panels.

- Carefully assemble the cabinet, ensuring all corners are square.

- Secure the joints with screws, countersinking them slightly.

- Cut a hole in the front panel for the woofer, using a jigsaw or router.

- Attach the woofer to the front panel.

- Install the speaker terminals on the back panel.

- Fill the cabinet with damping material.

- Attach the back panel.

Wood Selection for Speaker Cabinets

The type of wood significantly impacts the sound. Choosing the right wood is like picking the perfect filter for your coffee – it makes all the difference. Think of it as adding your own personal touch to the sound.

Here’s a comparison of popular choices:

- MDF (Medium-Density Fiberboard): Affordable, dense, and easy to work with. Offers good damping properties, reducing unwanted resonances. However, it’s not as aesthetically pleasing as hardwoods.

- Plywood: Strong, relatively inexpensive, and comes in various thicknesses. Offers a good balance of stiffness and damping. The layers can create some internal resonances if not properly braced.

- Birch Plywood: A step up from standard plywood, offering superior stiffness and damping properties, leading to a cleaner, tighter bass response. It’s a popular choice among high-end speaker builders.

- Hardwoods (e.g., Oak, Maple, Cherry): Aesthetically beautiful, but more expensive and can be more challenging to work with. They generally offer good stiffness and resonance characteristics, resulting in a warmer, more detailed sound. However, they might require more advanced woodworking skills.

Cabinet Bracing Techniques, Speaker cabinet design plans

Bracing is crucial. Think of it as the skeleton of your cabinet – it provides structural integrity and prevents unwanted vibrations that can muddy the sound. Without proper bracing, your cabinet will resonate like a drum, distorting the audio.

| Bracing Type | Description | Advantages | Disadvantages |

|---|---|---|---|

| Internal Bracing | Cross-braces or internal supports attached to the cabinet walls. | Increases rigidity, reduces unwanted resonances, relatively simple to implement. | Can reduce internal volume, potentially affecting bass response if not carefully planned. |

| External Bracing | Braces attached to the outside of the cabinet. | Doesn’t reduce internal volume, can add aesthetic appeal. | Can be more complex to design and implement, may affect the overall cabinet dimensions and aesthetics. |

| Dado Joints | Interlocking joints between cabinet panels. | Extremely strong and rigid, minimizes the need for additional bracing. | Requires precise cutting and joinery skills, more time-consuming. |

| Rabbet Joints | A groove cut into one piece of wood, allowing another to fit snugly. | Strong and relatively easy to create, good for adding stiffness. | May not be as strong as dado joints, requires careful planning. |